From left to right: EuroPunch pliers, BeadSmith hole punch pliers, and a screw-action hole punch

A new hole punching plier just crossed my desk, and honestly, I was a bit taken aback. We already carry several hole punch pliers, as well as a screw-action metal punch, so why did we need another one? Hopefully this blog will answer that question and help you decide which tool is right for you.

It wasn’t that long ago (maybe 2-3 years?) that it was really hard to find a simple hand tool to punch clean holes in metal. Luckily we now have several options. Here are the main factors to consider when choosing the best punch for your needs:

- Hole size/shape – what size wire and/or jump rings need to fit? The smallest (1.25mm) fits regular jump rings just fine, but there have been times where I’ve needed a slightly bigger hole.

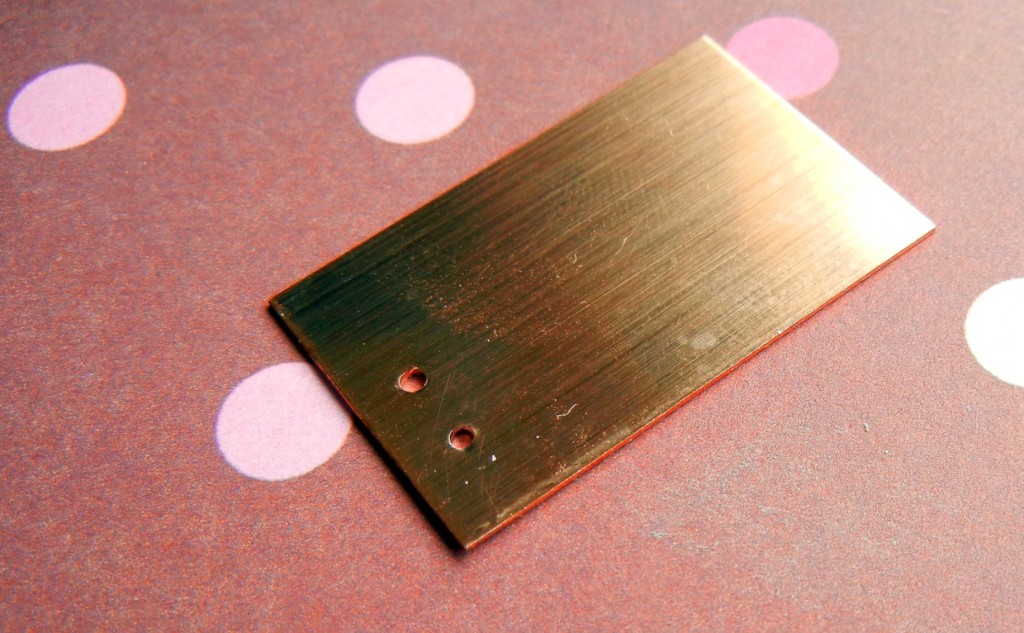

- Gauge – how thick of a piece of metal can you punch? All of the tools are designed for soft metal (such as sterling silver, copper, brass and aluminum). They can also be used on steel bottle caps, but doing so will wear out the punches more quickly. Remember, the bigger the gauge number, the thinner the metal (ex. 24 gauge is thinner than 20 gauge).

- Reach – how far from the edge of the piece you can punch a hole? It’s not really an issue if you are punching holes near the edge (most common), but if you plan to say, wire-wrap a stone onto the middle of a large metal sheet for a pendant, you might need to punch holes far from the edge.

EuroPunch pliers are available in 1.25mm and 1.8mm round, plus 1.5mm square and 1×1.7mm oval. Each pair of EuroPunch pliers reach about 0.5″ from the edge of your piece, and can punch through soft metal up to 18 gauge.

The BeadSmith punching pliers make 1.5mm round holes up to 3/4″ from the edge in soft metals up to 20 gauge.

The screw-action tool punches both 1.6mm (1/16″) and 2.3mm (3/32″) round holes, so it is really two tools in one. It is rated for soft metals up to 24 gauge. (We’ve successfully punched through pennies, which are close to 14 gauge, with this tool, but doing so will wear out the punch more quickly (just replace the punch, not the whole tool!). The screw-action tool reaches just a bit further than half an inch.

Speaking of replacing the punch…here is how you know it is time: the punch won’t quite punch all the way, leaving a little sharp piece you need to file off. You can buy replacement punches for any of the hole punch tools for just a few bucks.

It honestly doesn’t take much pressure to punch a hole with any of these tools, but if you have difficulty squeezing firmly, the screw-action tool might be the best choice. I think the pliers are a little quicker to use, though. The BeadSmith punch pliers also feature a “gauge guard” – a screw that you can adjust to keep the pliers from punching too deeply and marring the surface around the hole. It is a nifty feature, but one you have to remember to use! If you forget to adjust the gauge guard, you will probably mar your metal a bit from time to time.

BUT – here is a tip to keep your metal pristine no matter which hole punch you use:

Cut a little piece of plastic from the package the tool comes in, and punch through it. Then leave that little scrap on the punch (See image above). It effectively cushions your metal from the punch and removes all worry of marring your metal. If you forget, just buff the mark with some steel wool and it should disappear quite easily.

Happy punching! ~ Cindy

2018 Editor’s note: Links in the comments below have all been updated! (some of them broke when we upgraded our website)

38 Comments

What a clever idea to use a bit scrap plastic like that!

Hole punchers have been on my wishlist for ages, it feels like, but I just don’t seem to be able to decide which one (or which ones) to buy. One thing I like about the pliers is that you can get square and oval holes too. Seems a bit wasteful, though to buy one set of pliers for each type or size of hole. I’d like a tool where you have one set of pliers and then you just change bits for different size holes, like those hole-punch pliers for leather with a rotating wheel. But for metal and including oval and square holes.

I totally agree, maneki! When I replaced the punch on my round EuroPunch pliers, I actually considered trying to put in a replacement from a different shape to see if I could make it work. Unfortunately it won’t since the opposing jaw is shaped to match the punch. We’d be looking at a much larger, heavier tool if we could get a multi-size and shape one… but it would be great!

Great tutorial on metal hole punching! I am new to jewelry making and have

Been looking for an article like yours . Where do you buy your tools??

Hi Diane!

We (Rings & Things) sell the tools!

Both the plier punches:

http://www.rings-things.com/Products/?search=plier%20punch

and my personal favorite, the 2-hole punch:

http://www.rings-things.com/Products/?search=euro%20tool%20two%20hole%20punch

~Polly

Hi Cindy, Thanks for the great info. can you recommend which tool would be best to punch holes thru sterling silver, silver plated and silver flat wear to make bracelets from silverware(spoons, forks, etc). I bought a 2 hole punch from a hobby lobby but it doesn’t work at all.

Thanks, Mary

Hi Mary,

This two-hole metal punch (from Euro Tool) is the most durable punch I’ve found, that isn’t a power tool. It will punch through thick sterling silver with ease. It says it is only designed for up to 24 gauge metal … but it cuts through nickels and pennies like butter. Just don’t try cutting steel washers =) Or if you do, have replacement parts on hand.

This little punch may look like the one you got, but if yours didn’t say “EURO TOOL” then it’s just a cheap imitation, and we’ve heard that most of the imitations don’t work.

For the silver plated and silver flat wear … that’s tougher to answer. It depends on what is underneath the plating. If it is steel under the plating, then a hand-powered jewelry tool will not do the trick. You’ll need a drill press, and special drill bits designed for cutting through steel. A quick survey of google results tells me that drill bits that cut through steel “just happen” to be the most-expensive drill bits available, because standard steel drill bits can’t cut through steel — they may need to be titanium oxide coated or cobalt steel.

I believe that our drill press would work, but you should first find out what size drill bits are available for the materials you’re trying to cut. (The Jacobs chuck on the drill press accepts bits up to 6.5mm.)

I used the Euro tool and it broke on both punches with the 3rd penny. Disappointed …

Hi Page,

Although the EuroTool two-hole punch says it’s only good for soft metals up to 24gauge, I’ve used it regularly on much heavier metals (including pennies). The only thing I’ve broken mine on were 2 items that I did not realize were steel (none of these jewelry tools are designed to cut steel). One was a steel washer (I thought it was aluminum.) The other was a foreign coin with a steel core.

So I have a few questions:

1) After you cut an item with the 2-hole screw-action punch, do you a) pull your penny or other item off the tool, or do you b) carefully keep your punched item in place and completely unscrew the handle until the penny falls off the tool naturally? “b” is the recommended method. The manufacturers of the various screw-action punches say that if you use method “a” you will bend your punch, and once they are bent — even slightly — they will break.

If you used method “b”, I have another question.

2) Are you sure you have the Euro Tool 2-hole punch? Or could it be a knockoff? The “big box” craft stores regularly have similar-looking tools on sale for $3 to $8 but everyone I’ve talked to says the “big box knock-offs” are junk.

REMEMBER to anneal your metal first. Pennies have been work hardened from use and the stamping process. The easiest way is to mark penny with a sharpie and heat with any torch until sharpie disappears. Then quench in water. THEN punch holes!

Thanks Ken,

That’s a great tip. Often we recommend to anneal the metal, but rarely do we actually spell out what annealing is!

–Polly

How do you or what would you use to punch out more delicate pieces. I want to cut or punch out puzzle pieces.

Thank you.

Liane

Hi Liane,

You can use these same tools to punch holes in puzzle pieces. Although they are designed for metals, they work great on lighter materials too. I’ve used the Eurotool 2-hole punch on vinyl disk beads (like sequins but not as shiny), and leather bracelets with no problem.

Or – are you asking how to cut out puzzle-pieced shapes from some other material like card stock? If so, check your local craft store. I’ve seen puzzle-piece shaped punches/dies, but I don’t know what types/thicknesses of paper products (or maybe even thin metal!) they can be used for.

Just want to say thanks for all your generous help.

I just saw an article in Country Home mag and wanted to try me hand at the craft item. It called for euro punch.

You answered all the questions I had.

Now I am on my way to purchase the euro punch, thanks to you.

Sheila Hershon

Your blog is SO SO helpful to a newbie like myself. I am dabbling into jewelry design but recently I saw some pieces where I need to make holes for. However, I am so overwhelmed by it all. Are there any machines that allow for varied sizes. If not someone somewhere should design one because to have a machine that has a scale of holes would no doubt put an end to having 20 different size hole punchers.

Erica

Hi Erica,

The Eurotool 2-hole punch is my favorite, but it only makes 2 hole sizes (1/16″ and 3/32″). I really like how smoothly and easily it cuts.

If you need BIGGER holes, then the EuroPowerPunch is awesome. It cuts 7 sizes of circles (I call them circles because I consider them bigger than holes) from 3/32″ to 9/32″ – so the largest hole is a bit over 1/4″.

Great information!!! Now I am hoping to find a Canadian supplier. Any ideas?

Hi Carol,

We’re happy to ship to you in Canada! (We recommend you pick Post Office Priority Mail as your shipping method.) We have a little more info about shipping from the US to Canada here: http://www.rings-things.com/Shipping-International/#canada

Hi, what would you suggest I use to make holes in game pieces, such as Monopoly or Clue. I think they both are pewter. I am hoping a hand punch tool will work and I will not need a drill. Thanx for your help, Elizabeth

Hi Elizabeth,

I would suggest the EuroTool 2-hole punch (linked above). It works a lot like an unpowered drill. It punches through pennies, quarter, etc no problem, and pewter is very soft, easy to punch through with the EuroTool 2-hole punch. The only potential problem is that you’ll need to find a spot on the piece, that you can get the tool onto.

I don’t think the plier punches will work well.

Another option is a similar tool that has a deeper access point: http://www.rings-things.com/Products/?search=rivet%20punch%20tool%20crafted . It’s more expensive, because one end punches and the other end rivets. You only need the punching end for what you’re doing, but you can see that this tool is taller than the Eurotool punch.

Thanx for the information Polly 🙂

Hi,

I am currently looking for something to punch out 10-40 mm circles from sheet metal. Do you have any suggestions for what I can use?

Thanks,

Bailey

Hi Bailey,

It sounds like you’re looking for a disk cutter: http://www.rings-things.com/Products/Metal-Disk-Cutters/ . Our 11piece and 5piece both cut up to 1″ disks in 24g soft metals (like copper, aluminum, sterling and brass) — the others linked only cut up to about 5/8″. What metals, and what is the heaviest gauge of sheet metal you’re looking to punch? Anything over 1″ (roughly 25mm) in diameter gets hard to punch without the aid of hand tools.

~Polly

BTW, I found that when using the screw-action type of hole punch, if I put a little piece of parchment paper inbetween the metal disc and the punch, that it also protects it!

Hi LS,

Yes, that is a great trick! I haven’t tried parchment paper, but I’ve used bits of left-over 3×5 cards, and old business cards — they also work nicely to prevent scratches.

~Polly

Hi,

I’m wondering if you know of anything that would be easy to use to punch a hole in an ear cuff (1.25mm) without damaging the shape of the ear cuff.

Thanks, Sue

Hi Sue,

I am pretty sure the 1.25mm plier punch

(http://www.rings-things.com/Products/Drills-Bits-and-Hole-Punches/EURO-TOOL-EuroPunch-Pliers-Round-1-25mm-Hole.html)

would do what you need it to but I am not 100% sure.

The other thing that might work (but would be a lot more expensive to try!) would be the Crafted Findings riveting/piercing tool **with** a domed piercing base.

Base: http://www.rings-things.com/Products/Crafted-Findings-1-16-Domed-Piercing-Base.html

Tool: http://www.rings-things.com/Products/Crafted-Findings-1-16-Rivet-Piercing-Setting.html

~Polly

Hi Polly-do you have any suggestions on punching holes in small metal tins? I have a hand held hole punch that is very good for making holes in tins with slider tops. The slider top comes off and is thin enough to fit into the hole puncher. But the lids to small metal tins won’t fit. They are maybe 3/4- 1/2″ tall. I am looking for a nice clean punch so I don’t have to file down anything-lazy!! I looked at you punchers but couldn’t tell…

Thanks!

Hi Kate,

I’m sorry, I don’t have any inexpensive suggestions. I’ve been trying to figure out an easy way to punch metal tins, too.

I’m afraid that a drill is my only suggestion. We do have this nifty tabletop drill press:

http://www.rings-things.com/Products/Drills-Bits-and-Hole-Punches/EURO-TOOL-Benchtop-Drill-Press.html

but admittedly, spending $100 to upcycle cool tins, seems like overkill.

Also, the benchtop drill press would work great on Altoids and Scho-ka-kola tins, but not so well on skinny tins with slider tops like the Chimes Ginger chews.

~Polly

Hi, thanks for this ***great*** blog! So much good information here!

Here’s my question:

I’ve just been using my husband’s hand drill with the smallest bit to make holes in my 22 ga. sheet metal for the jewelry I create. I am currently working on some earrings that end in very small discs which I cut from the sheet. I need to drill one hole at the top of each. I have tried clamping them down with small clamps, I’ve tried taping them to my board with various tapes, I’ve even tried rubber cementing them to my drill board– but they just get stuck and spin round and round and I can’t keep them down to drill them! I’m going CRAZY. Does anyone have any ideas? I’m sure there must be an obvious solution that I’m just not thinking of… Any ideas are greatly appreciated!

Hi Donna,

I use a ring clamp to hold 2 pieces of metal together when I want them to be punched at the exact same spot. I don’t know if that would work for what you’re doing though. Here’s the ring clamp:

http://www.rings-things.com/Products/?search=ring%20clamp

I also think all of the “helicopter” or screw-type hole punches in this link are wonderful:

http://www.rings-things.com/Products/Drills-Bits-and-Hole-Punches/

(I don’t actually like the plier style very much, but I know some people like them a lot.)

~Polly

What punch would you recommend for making holes in plastic guitar picks?

Thanks!

Hi Danielle,

They would all work for something soft like a plastic guitar pick, but I prefer the EuroTool 2-hole screw-action punch (http://www.rings-things.com/Products/EURO-TOOL-Metal-Punch-Two-Hole.html) because it makes the smoothest holes — no rough spot or deformed surface.

Disclaimer: Don’t fall for the “big box” craft store versions that aren’t Eurotool brand. The tool may look simple, but I’ve heard from a lot of people that the $4 and $8 versions they got at the craft store simply don’t work (on any material).

~Polly

Hi, thanks for your information on hole punches. What I need to know is how to make a 1 mm (at least) wide hole in a flat disc shaped washer – the kind you get in the hardware store or have in a basement/garage tool box. I don’t know what gauge the metal is but I’m sure it’s thicker than jewelry sheet metal gauges, I guess it’s made from stainless steel?. I need it for earrings/pendant where I don’t want to just slide open center of washer thru a 10mm jump ring or wire wrap it. I don’t want anything covering the washer. Thanks for any info you can provide.

Hi Donna,

To drill holes in stainless steel, you will need drill bits from the hardware store, rather than from a jeweler.

Jewelry-maker’s cutting tools are made for drilling/cutting soft metals like sterling, gold, and copper.

To drill a hole in steel, I’ve seen recommendations for a cobalt bit, or a carbide coated or titanium coated bit.

Be sure to use a center-punch to mark your spot before drilling. Drill slowly, to help prevent work-hardening the steel you’re trying to drill through. You may need to replace the drill bits frequently, because you need a very sharp drill bit to cut steel.

As far as the drill itself, you can use a jeweler’s drill press, flex shaft (such as a Dremel or Foredom), or even a standard hand drill from the hardware store. Your hand will get very tired using a standard drill from the hardware store, but you can sure test the process out this way and see if you want to invest in the more ergonomic tools for a production process.

Now you know why we love our copper washers so much. =) They are a LOT softer and easier to work with. You can actually use the hand tools listed in this blog to work with them. We also have some sterling silver “ring” blanks, like this, mixed into our sterling blanks. They are much pricier than the washers from the hardware store, but you can use much less expensive tools to alter them, so it’s a tradeoff.

~Polly

Thank you Polly, I was afraid it was going to need a “heavy duty” tool. All of the videos I’ve seen on “washer” jewelry just have them hanging as pendants using a lark’s head knot with cord but I didn’t want to do that if I go to the trouble of painting/decorating it. I’m going to try a glue on bail on the back, even though glue may damage the decorated finish on the back. Going to try w/a duct tape decorated one first, less time invested if a fail to adhere.

Hi Donna,

2-part epoxies, although more time-consuming to use, are more durable — and less damaging — than most other glues. If you read the fine print on most glues, they will also say what they work best on (or what should be avoided). Each of ours is different. Epoxy 330 sets up fast, and dries clear — it’s great for repairing broken crystal figurines. Epoxy 220 dries a little slower, is amber colored, and has a stronger bond. It’s worked great on everything I’ve tried it on; you just have to be careful not to let any spill over the edges or you see that yellowish tinge. Our classic Rings & Things epoxy is great. I still have jewelry made in the 80s that was glued with this stuff. Downside: due to its “set” time, I prefer it for big batches, like gluing 50+ items and then setting them someplace safe to dry for 24 hours. The Hammerhead epoxy, I haven’t actually used, but everyone I’ve talked to likes it … and it’s shippable via any shipping method. (You have to pick UPS Ground for the others.) ~Polly

Hi There!

I’m looking to start making my own guitar pick neckalce jewellery. Was wondering if this tool would be suitable to punch holes in guitar picks?

Thanks so much!

Justin 🙂

Hi Justin,

Yes, all the hole punches listed here are suitable to punch holes in plastic or wood guitar picks, or guitar picks made of other similar soft materials such as tagua nut and other forms of “vegetable ivory”. If they are specialty guitar picks made of metal, then first check to see what type of metal, and follow the precautions above. I’ve heard that some guitar picks are even made of glass. You would need to use a drill press for those, and be sure to keep the glass item underwater while drilling, to help keep it from overheating and shattering (and also to prevent breathing glass dust).