If you are looking to expand your tool selection, Wubbers® Pliers are a great addition to any jeweler’s bench. The pliers have comfy padded handles, are made of high quality stainless steel, and have box-joint construction. Wubbers offers traditional jewelry pliers in two sizes (which are awesome), but the pliers that caught my eye are the mandrel pliers. Mandrel pliers are available in several shapes and sizes. And best of all, they are perfect for forming wire links, like those featured in designer Polly Nobbs-LaRue’s two blog posts on making soldered-link bracelets: “I Love Copper Solder!” and “Copper Soldering Tutorial – Part 2”.

“Captured Aventurine” Bracelet Tutorial by Rings & Things’ designer Polly Nobbs-LaRue

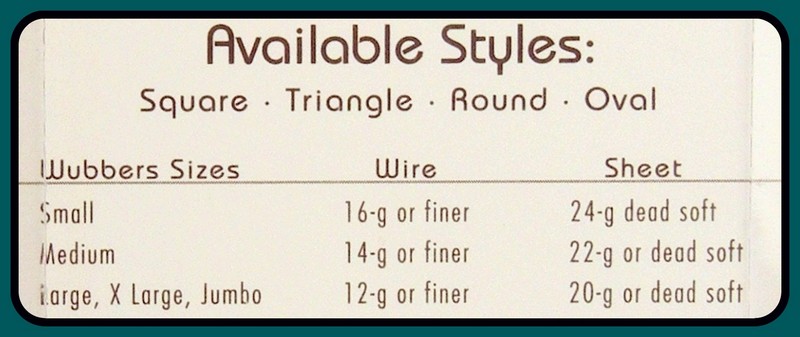

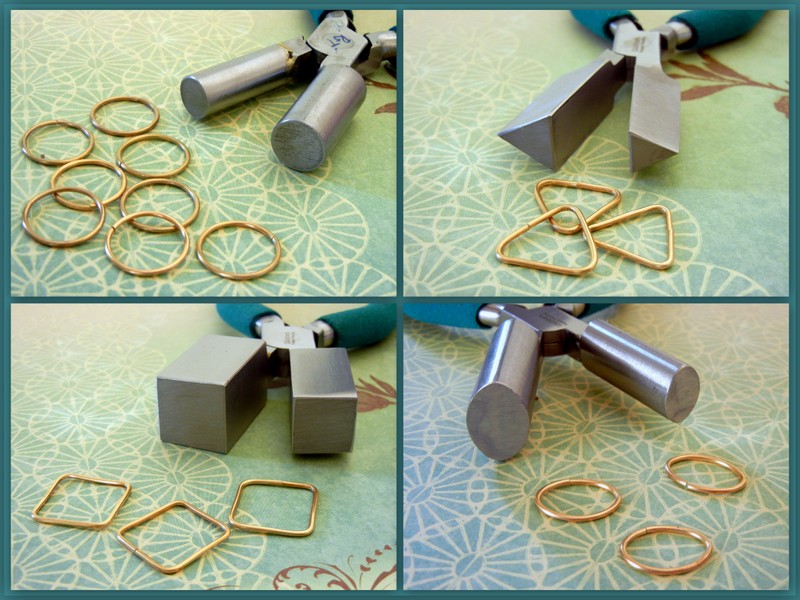

Wubbers mandrel pliers are available in several shapes: round, square, triangle, oval, and half-round (not pictured). Each shape is available in a variety of sizes. Plus each pliers’ jaw has two mandrel sizes.

Check out the Wubbers packaging for gauge recommendations and an access code for Wubbers University.

An added bonus: inside each package is your invitation and access code for free online classes and tutorials at Wubbers University! You will find a wide variety of classes for the beginning to advanced jewelry maker; just what you need to build new skills.

Follow the wire and sheet metal gauge recommendations for your size of mandrel pliers — an easy to follow chart is featured on each package.

Recommended tools for the jeweler’s bench:

- Nylon-jaw flat-nose pliers for straightening the wire

- Wubbers mandrel pliers for forming the wire

- Jewelers saw frame and saw blades for cutting the wire

- Swivel vise for holding the wire coil (and so many other valuable tasks!)

- Bench pin for holding the wire coil

- Flat-nose and chain-nose pliers for aligning the cut wire ends

Follow these steps to form and cut wire links using Wubbers mandrel pliers and a jeweler’s saw:

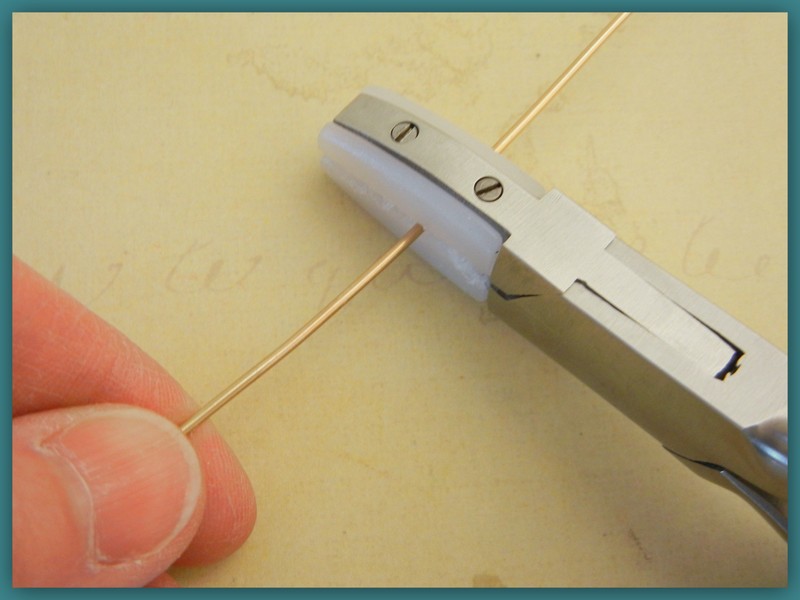

Step 1: Begin by straightening the wire. Pull the wire through nylon-jaw flat-nose pliers to easily straighten it. If you are planning to solder your links, avoid plated wire; instead use solid brass, copper, nickel, sterling or silver-filled wire.

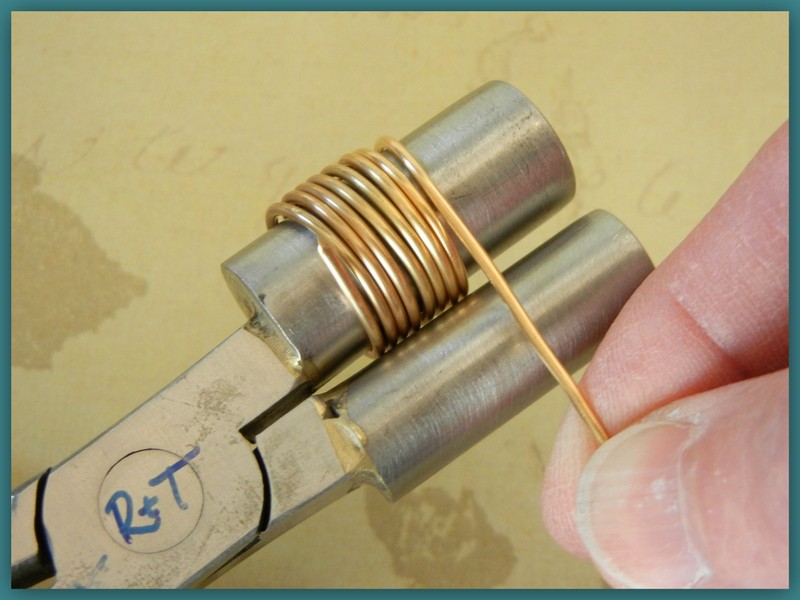

Step 2: Begin wrapping the wire around your mandrel of choice. As you coil, maintain even pressure so the links come out uniform. With the round mandrels, you can rotate the wire on the mandrel to make a continuous coil; for other shaped pliers, you will need to open and close the pliers’ jaw with each complete pass.

Step 3: Continue coiling the wire. Make a coil that is two wraps more than the number of links you need; the first and last coil will not make a complete link.

Step 4: Pinch the wire coils tightly together, and apply a layer of low-tack masking tape around the coil. This will keep the wire in place while sawing. Slide the taped coil off the mandrel pliers.

Step 5 – Version A: Attach a swivel vise to your workbench and place the wire coil in the padded jaw. Gently tighten the jaw so the wire coil is held firmly in place–but not so tightly the coil becomes misshapen. Thread your jeweler’s saw with the blade’s teeth facing down and out. You are ready to begin sawing. To avoid nicking the wire, angle the saw blade slightly so the blade only touches the wire being cut.

Step 5 – Version B: Attach a bench pin to your workbench and firmly hold the wire coil on the edge of he pin. Use a jeweler’s saw to cut the wire coil from top to bottom. To avoid nicking the wire, angle the saw blade slightly so the blade only touches the wire being cut.

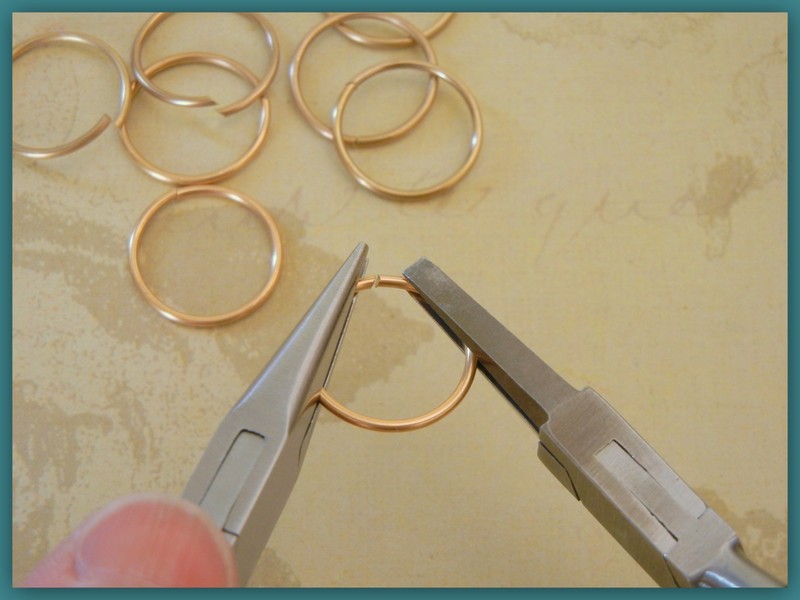

Step 6: Use flat-nose and chain-nose pliers to align the cut ends of the wire links. The cut ends need to fit snugly together for soldering. Your wire links are ready to solder.

Make things!

Mollie

4 Comments

These tools for wire cutting and shaping are great for those people who do crafts or small jewelery projects, but do you know there are companies that provide people with those services? Laurel Wire Company is one of them! They can help you with all of your wire cutting and straightening needs regardless of the amount you might need.

Hi Laurel Wire,

Most “ad” replies to our blog articles are totally off topic, so I delete them, but yours is relevant and I think could be quite useful.

I have heard many of our local customers say they have troubles with their hands and can’t do as much wire handling as they would like, so your service could be a hand-saver to wire workers who need help cutting and straightening, so they can still do the fun parts.

~Polly

How might I purchase these Wubbers Pliers?

Hi Sandra,

Normally you can buy them at our website: https://www.rings-things.com

Although, at the moment (8/16/2022 noon) our website is having some issues.

–Polly