Blink and you miss it – March is already behind us! Here in Spokane we were teased with one gorgeous sunny day last weekend…following by a week of pouring rain. The Bead Show crew has found pockets of nice weather here and there, but spring is a most changeable season.

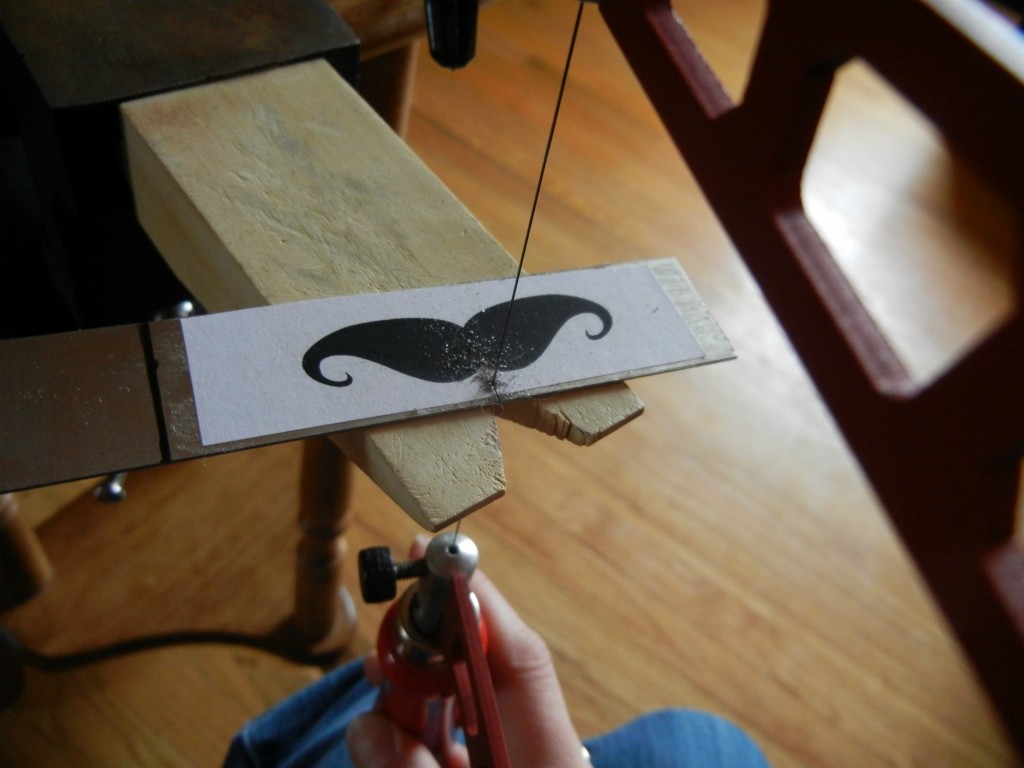

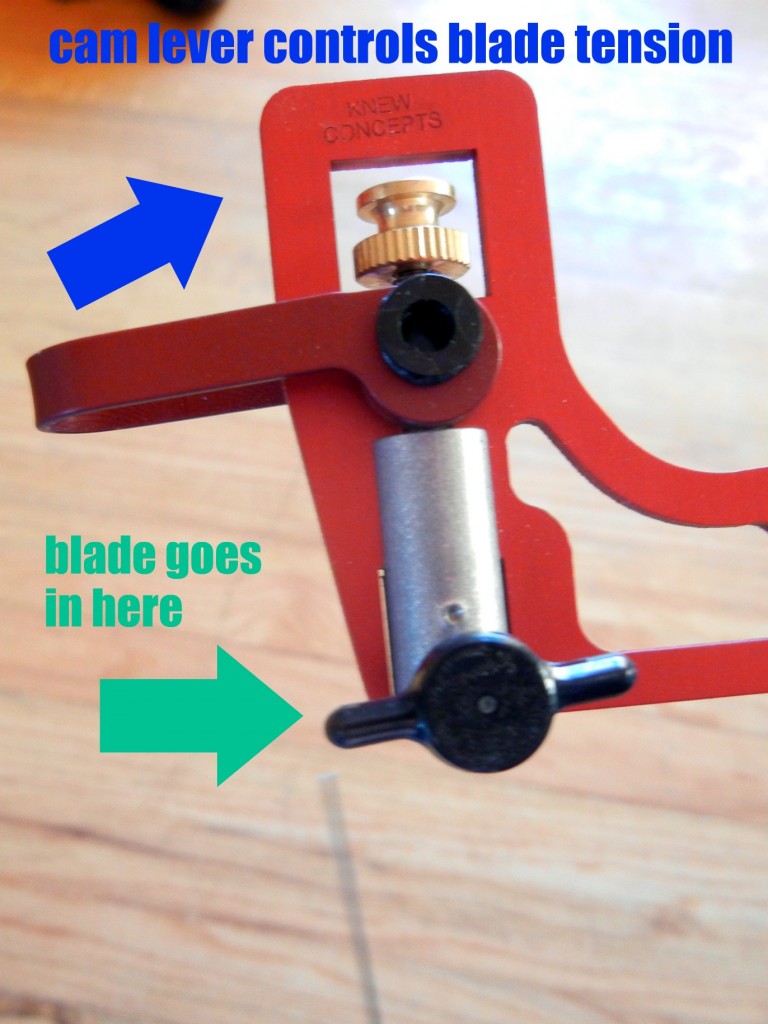

I had a lot of big plans for what I wanted to accomplish this week, but they’ve gotten derailed by the need to do some basic computer housekeeping. I’m not going to admit to how many pictures I have saved on my hard drive – I mean on the network. Yes, I always make sure all my files are backed up on the network drives! That’s right techs, no worries here! But um, yeah, it is always a good idea to purge old files periodically. So that’s what I’m doing and I just happened to find this picture of a necklace I made in February and neglected to post. I used the new Knew Concepts saw frame to cut a fiddle-head fern shape from nickel silver and soldered it to brass sheet metal with a Blazer micro torch.

I had a lot of big plans for what I wanted to accomplish this week, but they’ve gotten derailed by the need to do some basic computer housekeeping. I’m not going to admit to how many pictures I have saved on my hard drive – I mean on the network. Yes, I always make sure all my files are backed up on the network drives! That’s right techs, no worries here! But um, yeah, it is always a good idea to purge old files periodically. So that’s what I’m doing and I just happened to find this picture of a necklace I made in February and neglected to post. I used the new Knew Concepts saw frame to cut a fiddle-head fern shape from nickel silver and soldered it to brass sheet metal with a Blazer micro torch.

The message “unfurl” seems especially appropriate today – what looked like dead branches just a week ago are now alive with new growth. Spring has sprung! Hope your creativity is unfurling as well ~ Cindy