It is great to have choices – but sometimes comparison shopping is such a chore! We recently added two new Blazer brand micro-torches. While our selection of three butane torches isn’t exactly overwhelming, it still raises questions. Why choose one over the other two? They all look about the same … and in many ways, they are the same:

- No appreciable differences in height, width or diameter.

- All three use triple refined butane (buy it locally due to shipping restrictions).

- All three include a plastic stand for hands-free operation.

- All three have flame adjustment options.

However, in several important ways, these three little torches do differ. The most obvious way is in price: the Blazer costs over twice as much as our original little torch. In fact, you can buy an entire mini torch kit, which includes a torch, soldering blocks, a tripod with mesh, tweezers and soldering pick, for less than the Blazer torch. Yet …

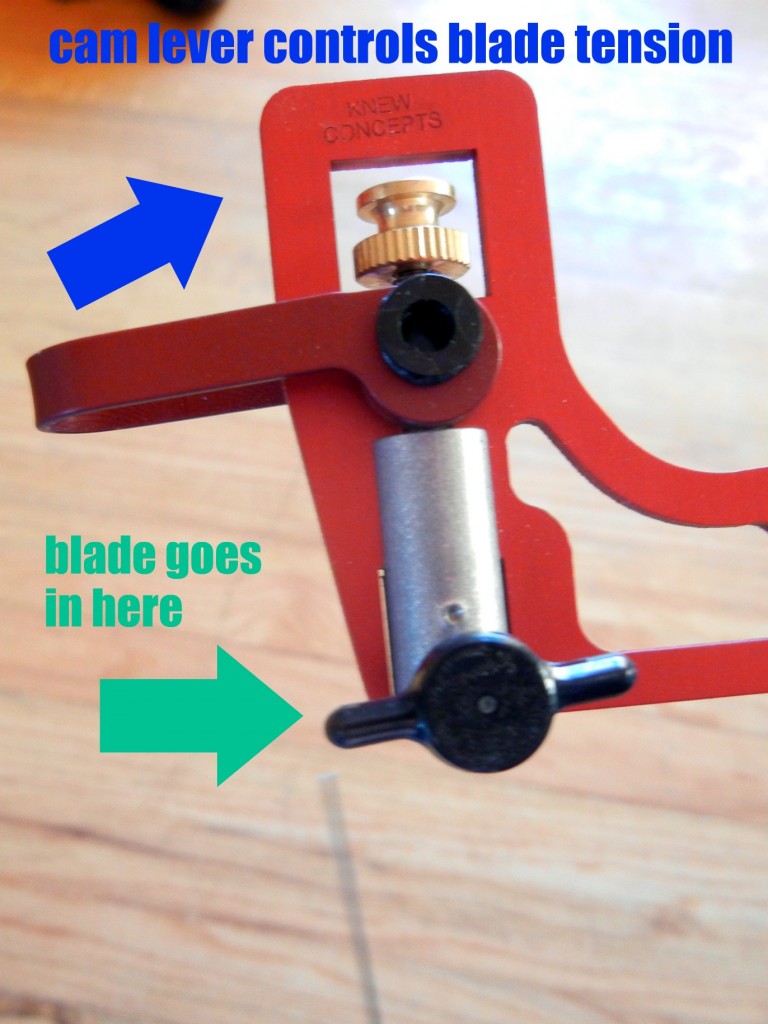

The Blazer is by far the easiest micro torch to use! It is a professional model torch, not designed for home use. It doesn’t have a child safety lock, so if you have any concerns about unauthorized use of your tools, this might not be the best choice (I hope it goes without saying you should keep any torch out of the reach of children). However, if you hate fumbling around with levers and buttons, then you will *love* the black Blazer torch. It has a really high quality ignition system. I won’t go into boring details on that. Just know that, while trying to do a fair comparison of the three torch options, I kept instinctively reaching for the Blazer because it was just more fun to use. Good design works! Plus, its burn time is about double that of the entry-level micro torch. Refilling butane is the least fun part of using a micro torch, so that detail counts for a lot in my opinion!

I really wanted to like the Stingray model the best – it is my favorite color after all! – but the safety lock and flame control just weren’t my favorite. So if budget is the biggest factor, the our original micro torch is still a great deal. It gets the job done. But if you can afford to splurge a bit, the Blazer torch is a tool worth owning. And if you truly want middle of the road performance and price – with the prettiest color! – then the Stingray fits the bill.

Here’s the stats in handy bullet form, with torches listed from Highest/Greatest to Lowest in each category:

- Burn time: Blazer, Stingray, Basic

- Price: Blazer, Stingray, Basic

- Ease of use: Blazer, Stingray, Basic

- Safety lock: Basic, Stingray, Blazer

Whether you want to fire small Art Clay silver pieces, torch enamel, solder metals or fuse fine silver, a micro torch is a great introduction to using heat! Here’s a little tutorial on making ball-end head pins to get you started. ~ Cindy