Shop for everything you need for this project here!

Tools:

Materials:

Additional Supplies:

Instructions:

You can leave a little of the center without texture if you want, since the brass sheet will cover this part.

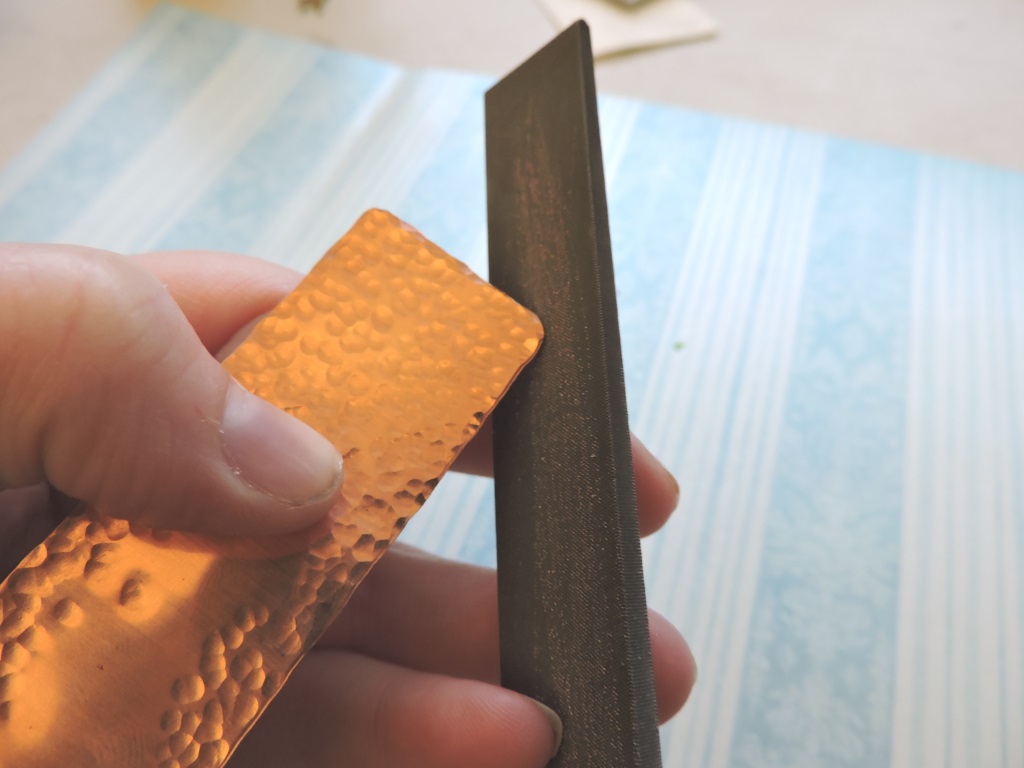

Using your metal shears cut a strip of the fancy textured brass sheet metal off. Cut it about 3/4 inch in width by 4 inches in length (that is the length the metal is sold in).

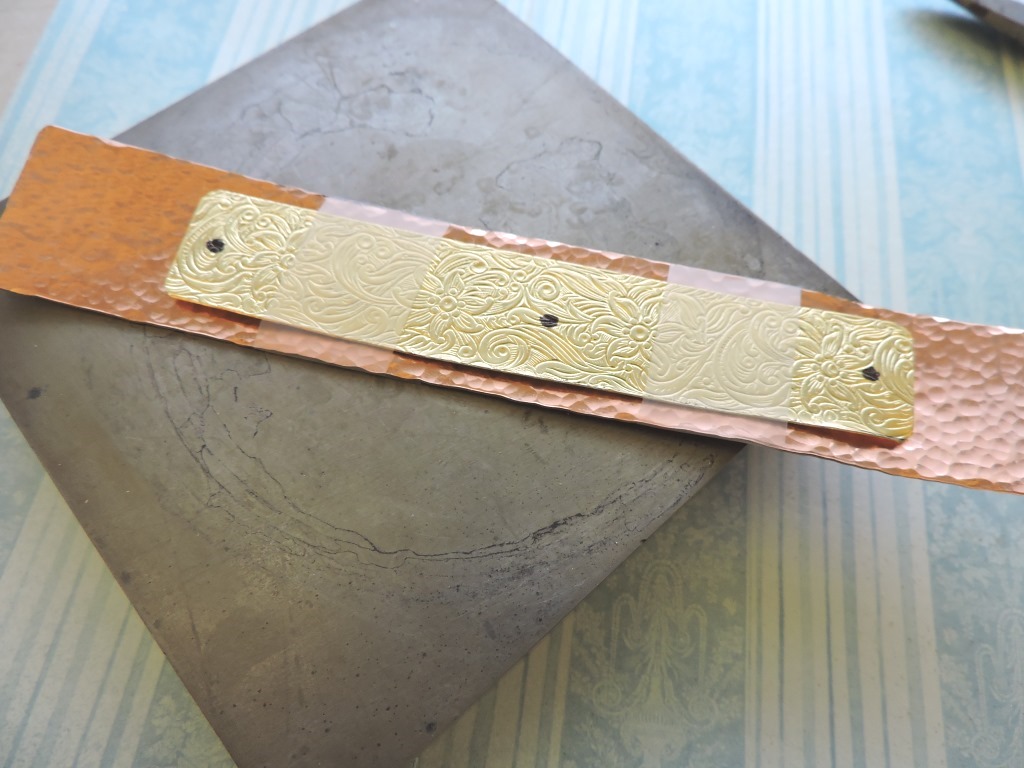

After you have filed both pieces, center the brass piece on the copper piece. Tape them together, and make three marks with a permanent marker like below. One in the center, and one on each end of the brass.

Use the riveting side to rivet the pieces together at these three points. It is really easy to use. Put the smooth end of the rivet (the end that looks like a nail head) on the brass side. The rivet will sit in the bottom of the tool, and when you turn the handle, the tool will smash the metal down, connecting the two pieces.

Now dip the piece in the Novacan Black to antique the metal. It will turn black like this. Rinse it with water, and dry it off.

Use the pliers to bend the ends around. Go back over the bracelet with the pliers until you can get the shape smooth.

Completed bracelet! The last step is to seal the metal, if you want. If you have any sensitivity to copper, I recommend this step. Using the resin spray, just give the bracelet a quick spray. I only seal the inside of the bracelet, but you can seal the front/outside too if you want. Just know that where you have sealed the metal, it will not naturally patina. It will stay as is.

Well I hope you enjoyed this tutorial! I love this bracelet! I think is has a slightly country western, shabby chic look to it. And you could definitely change the feel of it by changing out to one of our other textured brass sheets as well. If you like playing with sheet metal, check out these other projects below! ~Tiffany

Scotch Peak Earrings Tutorial by Amy Mickelson

Live with Intention Bracelet Tutorial by Polly Nobbs-LaRue

4 Comments

This is a really cool blog, I have been thinking of this type of design for a while, Would love to use swirly designs with personalization and mixing metals. I shall have to read the blog about riveting.

Stuart,

Thank you! The riveting tool makes it so easy! One side makes the holes in the metal and the other side rivets them together. It you are wanting to play around with it, I recommend getting a variety pack of the 1/16″ rivets in your choice of finish. Depending on how thick and how many layers of metal you are riveting, you need different length. Here is the link to the blog about the riveting tool, https://blog.rings-things.com/2013/07/22/best-riveting-tool-set/.

~Tiffany

Hi Tiffany, I see this post is about 4 years old, so I hope someone’s still getting notifications. Anyway, I just used 2 handmade copper rivets to attach a piece of stamped copper bracelet blank to a 3/4” x 6” aluminum bracelet blank. When I went to bend it all together with the bracelet bending pliers, one of the rivets popped apart. And I see your two pieces stayed together. Does it have to do with the thickness of the metal? So, just wanted to comment about that, going to go back and anneal both and will bend separately and fumble with riveting after. I made my own balled-end copper rivets and those worked wonderfully, until bending …

Hi Alysen,

There are a few possible factors, and I’m not sure which played the largest role, but they may have all played some part.

I’ve never had a rivet pop apart (but I’ve had some with a too-small head, pull through).

I’ve also always used fairly heavy gauge wire, and I’ve never used torch-formed ball-end rivets. So those could be 2 factors.

What wire gauge was your rivet? And what method did you use to create the ball end? (anvil and hammer, or torch?)

How thick were the gauges of sheet? (This would somewhat affect the total metal movement as the piece on top has to curve farther than the piece on the bottom, which tugs on the rivet.)

Torch-formed ball-end copper rivets are a bit brittle, so if they were torch formed, this was probably the culprit, when added to the amount of extra metal movement in the top piece compared to the bottom piece.

The rivets in the 2 bracelets pictured above are approximately 14-gauge brass, so if your rivets are a lot thinner they may not be sturdy enough to withstand curving the bracelet.

–Polly

Rings & Things